The Design

A mess of Standards

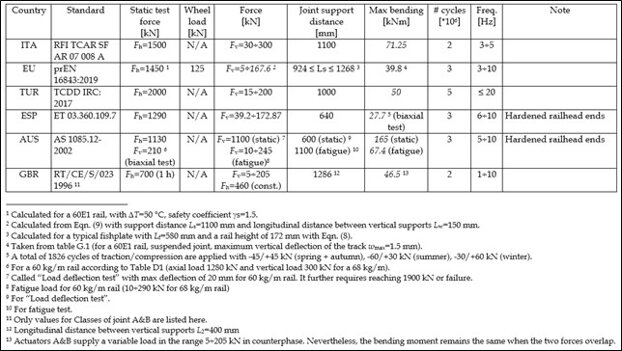

Each country uses a different standard, but none of the current standards may replicate what exactly happens on the field. All these tests try to be equivalent to real loads but as a matter of fact they are all unsuccessful, as all homologated IRJ joints continue to fail in service.

We decided therefore to use the European Standard EN 16843:2024 and the Italian (RFI), Austrian (OeBB) and Turkish (TCDD) infrastructure managers standard.

Sophisticated analysis required!

Young engineers simulate everything, but the new joint is complex --- like all the other joints!

From chain of tolerances to sophisticated structural calculations to contact mechanics...

Our expert analyst , Dr. Eng. PhD Gianluca Megna, has developed over the last ten year all the skills needed to make the simulations with the highest confidence to get reliable results in all these fields.

Looks easy but it's not

CAD modeling first!

CAD modeling is intimately linked to machining and assembling. All components were evaluated considering single and combined tolerances. Assembly sequence is particularly important --- the glue solidifies in 25-30 minutes so everything must run smoothly!!!

The Finite Elements...

Meshing the joint

Meshing is extremely important --- no need to say!

We implemented various strategies to reduce the number of elements while getting smooth and reliable simulations. We can simulate any kind of existing and future joint according to your needs.

Contacts management

Interpreting the results

The interface between bodies is highly non-linear as slip conditions may be reached during the tests and during the service. A large amount of time was spent to get the correct behaviour of the various components.

Losses of contact, non linearities in the material behaviour, large displacements and preloads require a large experience to accept or to reject the results that are in any case generated by a FEA simulation. In many occasions the simulation strategy was changed to achieve "reasonable" results that match with teh theory of stresses and strains.

Contact Mechanics

or how wheels and rails talk to each other

Contact patch doesn't lie

IRJ - sounds bad!

ABJ - is it eternal?

The idea of sharing the loads between the two half-joints was verified by an accurate modelling of the contact. The wheel touches initially on one half joint (left), then moves smoothly to the other one.

Impact noise at conventional IRJ is given by large impact forces. Simulations confirm the abrupt change during a wheel pass-by. Rail damage, noise and vibrations are generated.

The "handover" process in the ABJ is smooth as expected. No peak forces, no noise, no vibrations.

Stresses are so low that linear behaviour is retained --- no plastic deformation and therefore no damage accumulation.

What's next?

Once we reached the conclusion that

1. the idea is feasible

2. it solves a problem that still exists after 200 years of railways

3. The patent was on its way and intellectual property was secured

we decided to produce some joints and test them. See next page!

Copyright Andrea Bracciali 2025